The crane automatic control system belongs to the field of automatic control technology. Intended to solve the problems of existing technology being unable to remotely command cranes, manual command being labor-intensive, and equipment troubleshooting being troublesome. The automatic control system of the crane of this utility model includes a central processing module, an action command module, a detection module, and a display module. The control module is respectively connected to the action command module, the detection module, and the display module.

The beneficial effect of this utility model is to achieve remote command and control of the crane, ensuring the safety of the production process and improving work efficiency. The system architecture of LC+frequency converter+sensor+positioning system can achieve manual/semi-automatic/fully automatic operation switching of remote operation/local operation/remote control operation.

Main technical content and characteristics

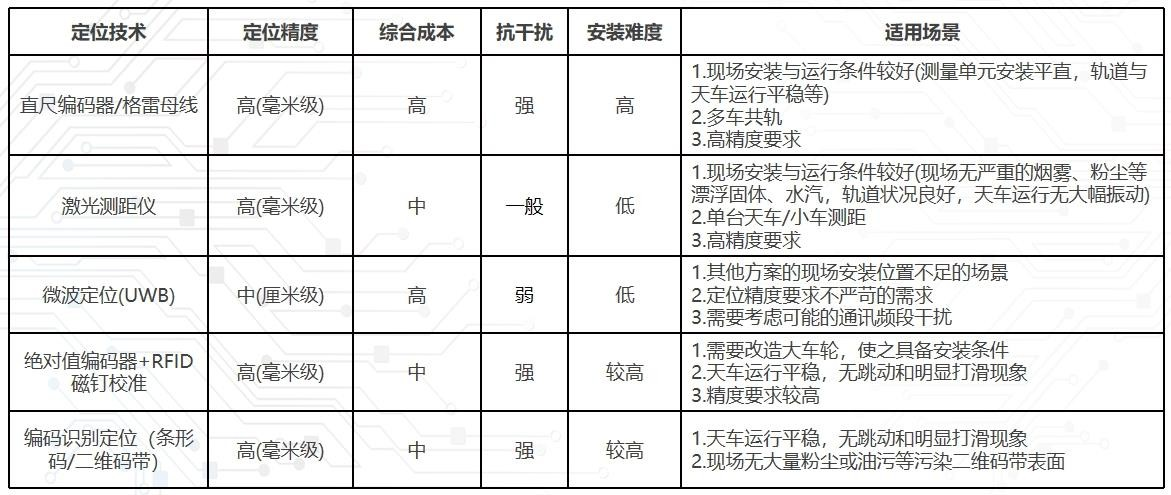

1. Precision positioning technology

The positioning of the overhead crane includes position detection in three directions: the crane, the trolley, and the main hook. The X-axis positioning measures the distance traveled by the crane, the Y-axis positioning measures the distance traveled by the trolley, and the Z-axis positioning is used to measure the height of the crane clamp from the ground. The accuracy of positioning not only directly affects the correctness of lifting actions, but is also closely related to safety production. The commonly used positioning techniques are shown in the table below:

2. Wireless communication technology

The control system needs to monitor the real-time operation status of the train, so it is necessary to use wireless local area network communication technology to send the real-time position and sensing weighing data of the train, and receive action instructions from the control system. The data transmission in the unmanned overhead crane system must meet the requirements of reliability, stability, and real-time performance. At the same time, due to the large number of equipment in the entire storage area, it also needs to have the function of multiple node networking communication.

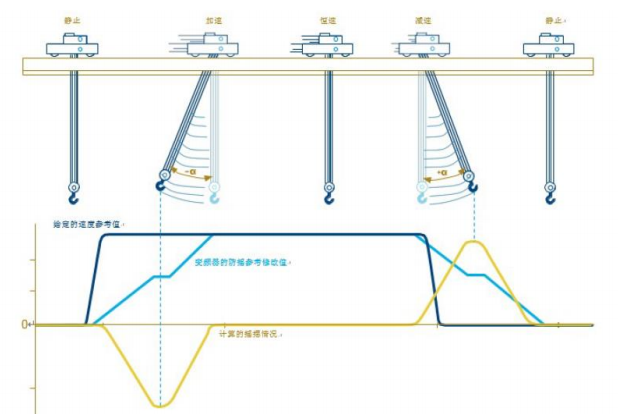

3. Anti sway control technology

During the actual operation of the crane, the grab bucket swings significantly in both the direction of the trolley and the direction of the crane, seriously affecting the efficiency of the grab bucket crane operation; The grab anti roll system can effectively solve such problems.

The anti roll system can meet the following requirements: under automatic working conditions, regardless of whether it is unloaded or overloaded, the electronic anti roll system can control the swing amplitude of the grab within ± 100mm and tend to come to a standstill within one cycle of the grab swinging from full speed to complete stop. Electronic anti roll system

The electronic anti shake program can be preset in the built-in programs of PLC and frequency converter for anti shake control. After the crane starts running, the control program couples the position and speed loops of the transfer function to ensure that the positioning system has an accuracy of 1mm while the locomotive bottom sway is less than 30mm. At the same time, the swing stops within 3 swing cycles, and the positioning accuracy is within 20mm after stopping.